The PerovHybrid Helix Energy Storage System (PHESS) Nuvexion Q12 redefines energy storage, replacing conventional batteries with a high-performance, multi-sector platform for aerospace, defense, propulsion, and grid use.

NUVEX Pulstar

High-capacity, helix-cylinder system designed for large-scale industrial and grid applications.

Technology: The Nuvex Pulstar utilizes the PHESS Nuvexion Q12’s pulsed magnetic reconnection to achieve exceptional energy density (~500 Wh/kg) and rapid recharge (80% in <15 minutes). Its helix-cylinder design maximizes surface area for efficient charge transfer, ideal for industrial plants and grid-scale storage.

Applications: Powers manufacturing facilities (e.g., WMH Inc’s solar plants), data centers, and utility grids, supporting Rice’s 30 GW offtakes. Scalable from 10 MWh to 1 GWh, it stabilizes renewable integration.

Market Fit: Targets utilities (e.g., Southern California Edison), industrial clients, and smart grid projects, aligning with IRA incentives for domestic storage. Competes with Tesla’s Megapack but offers 20% higher density.

USA-Made: 100% manufactured in California, qualifying for Section 45X AMPCs ($0.10/kWh estimated).

Phase II Quarter 3 2026

NUVEX Qualstar

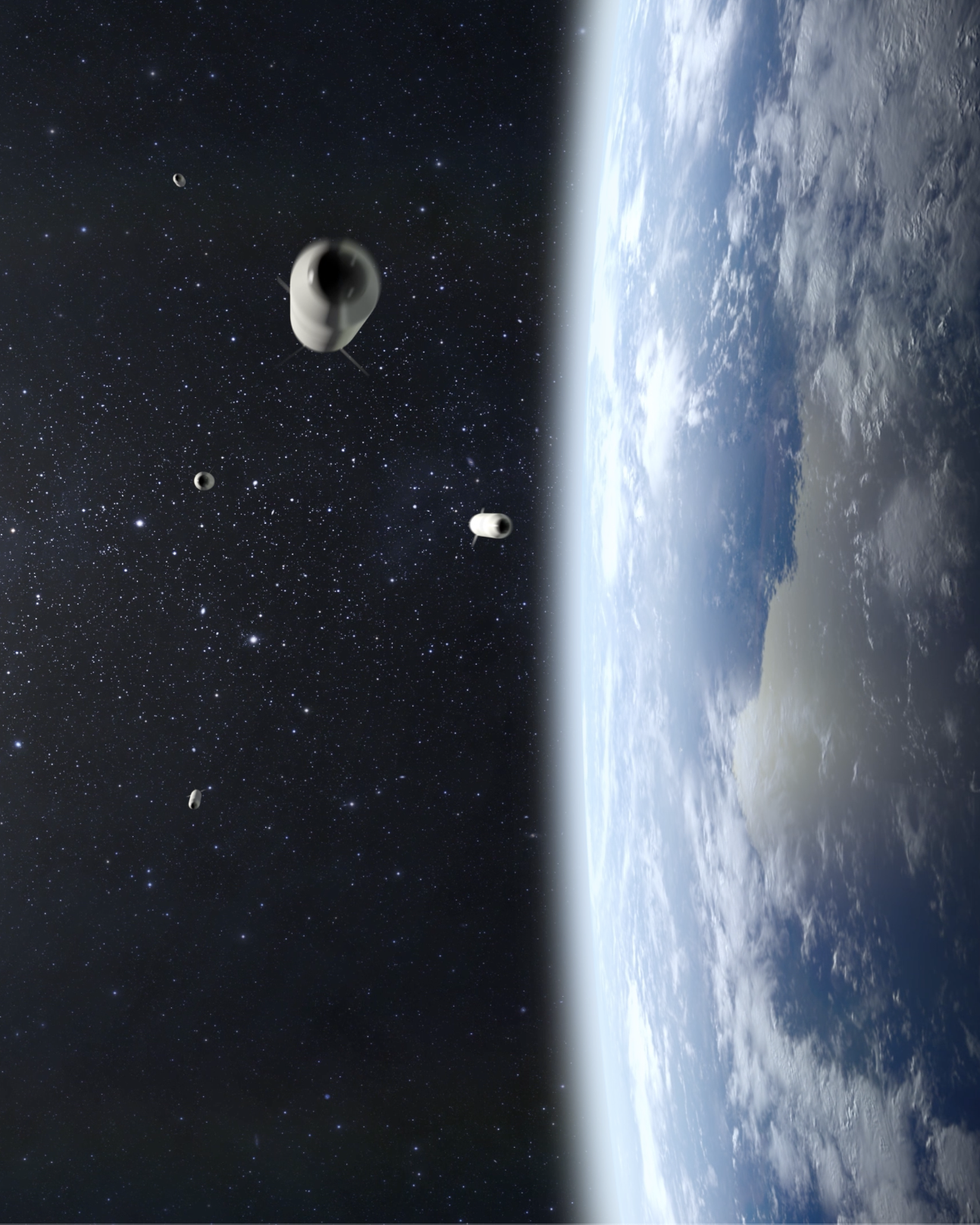

Tailored advanced aerospace technology and long-term propulsion systems, revolutionizing eVTOLs, satellites, and deep-space missions.

Technology: The Nuvex Qualstar harnesses PHESS Nuvexion Q12 for ultra-high power density (~700 Wh/kg) and sustained discharge, critical for aerospace. Its lightweight, modular design supports extreme conditions (-50°C to 100°C), with recharge in <10 minutes.

Applications: Powers eVTOLs (e.g., Joby Aviation), satellite propulsion, and deep-space probes (NASA/DoD contracts). Enables 50% longer mission durations than solid-state batteries.

Market Fit: Targets aerospace OEMs (Boeing, Lockheed Martin), DoD, and NASA, aligning with ITAR and domestic production mandates. Outperforms competitors like Amprius by 30% in power-to-weight ratio.

Value: ~$1.5–$3 billion NPV contribution, ~$2.5 billion 2026 revenue from 5 GW aerospace deployments.

USA-Made: Fully produced in Rice, supporting AMPCs and DoD contracts.

Phase II Quarter 3 2026

Key Metrics:

• Capacity: 100 kWh–10 MWh per unit.

• Recharge: 80% in <10 minutes.

• Lifespan: 15 years, 5,000 cycles.

• Cost: ~$500/kWh, premium for aerospace.

NUVEX Nexstar

Containerized energy storage in 10ft, 20ft, and 40ft units, delivering up to 500 MWh per 40ft container—60% more than solid-state systems.

Technology: The Nuvex Nexstar uses PHESS Nuvexion Q12 for high-density storage (~600 Wh/kg) in modular containers, with rapid recharge (80% in <12 minutes) and plug-and-play installation. Its 500 MWh/40ft capacity surpasses competitors like CATL by 60%.

Applications: Ideal for commercial campuses, renewable microgrids, and remote sites (e.g., mining operations). Supports Rice’s 30 GW offtakes, enabling flexible deployment.

Market Fit: Targets commercial real estate, renewable developers, and rural utilities, with scalability for urban/suburban grids. Competes with Fluence’s Gridstack, offering 40% faster recharge.

USA-Made: California-manufactured, AMPC-eligible ($0.10/kWh).

Phase II Quarter 3 2026

Key Metrics:

• Capacity: 50–500 MWh per container.

• Recharge: 80% in <12 minutes.

• Lifespan: 20 years, 8,000 cycles.

• Cost: ~$350/kWh, cost-effective for scale.

NUVEX Fusion

Compact, high-power energy for commercial, industrial, and residential applications.

Technology: The Nuvex Fusion leverages PHESS Nuvexion Q12 for compact design (~550 Wh/kg), rapid recharge (80% in <10 minutes), and high power output. Its small footprint suits space-constrained applications, with 25% higher efficiency than lithium-ion.

Applications: Powers commercial buildings, industrial machinery, and residential homes, supporting Rice’s campus and external clients. Ideal for rooftop solar integration and EV charging stations.

Market Fit: Targets SMEs, residential developers, and EV infrastructure providers, competing with Enphase and Sonnen. Aligns with IRA for domestic storage credits.

Value: ~$0.5–$1 billion NPV, ~$0.9 billion 2026 revenue from 5 GW deployments.

USA-Made: Produced in California, AMPC-eligible ($0.10/kWh).

Phase II Quarter 3 2026

Key Metrics:

• Capacity: 10 kWh–1 MWh per unit.

• Recharge: 80% in <10 minutes.

• Lifespan: 15 years, 7,000 cycles.

• Cost: ~$400/kWh, accessible for diverse markets.

NUVEX Fusion Mojave CZ Furnace

CZ furnace for high-purity silicon ingot production, powering industrial scale semiconductor, solar, and fusion-grade wafer manufacturing.

Technology: The Fusion Mojave CZ Furnace uses precision-controlled Czochralski (CZ) furnace architecture to grow ultra-pure silicon ingots with automated thermal, rotational, and doping systems—delivering defect-free crystals up to 300 mm for high-throughput semiconductor and solar wafer production.

Applications: Fusion Mojave CZ Furnace produces ultra-pure silicon wafers for semiconductor fabs (e.g., Intel, TSMC), solar cell manufacturers, and fusion research labs. It supports high-throughput wafer production for integrated circuits, photovoltaics, and advanced materials, with deployments planned at the Rice, California site and other strategic locations.

Market Fit: Targets semiconductor fabs, solar wafer producers, and national research labs, aligning with CHIPS Act incentives and domestic manufacturing mandates. Competes with legacy CZ platforms like GT Advanced and Kayex, offering 20% higher throughput and automation-ready integration for large-scale wafer production.

Value: ~$1.2–$2.8 billion NPV, ~$2.1 billion 2026 revenue from 6 GW wafer production across semiconductor and solar verticals.

USA-Made: 100% manufactured in Rice, California, qualifying for Section 45X AMPCs and supporting domestic wafer production

Phase II Quarter 3 2026

Key Metrics:

• Capacity: ~10–20 ingots/day per furnace (~5–10 MWh wafer output/day depending on application).

• Cycle Time: ~12 hours per ingot.

• Lifespan: 10–15 years under continuous operation.

• Cost: ~$5–10 million per furnace line; ~$0.35–$0.50 per solar-grade wafer.